Hydropower – an important part of the future’s energy supply

Hydropower extracts energy from water that flows in our rivers. It is an energy source that we can store and control, an aspect which is fundamental. When it rains and when snow melts during the warmer seasons, the water flow increases. We then store the water in dams and reservoirs, to subsequently release it and create energy when it is most needed during cold winters.

The sun is the main source of hydropower. When the sun heats the surface of lakes and seas, the water evaporates and forms clouds that then release precipitation in the form of snow or rain in areas of high ground. On the way back down towards lakes and seas, the precipitation flows via streams and rivers to the water reservoirs that are next to the power plants where we produce our electricity.

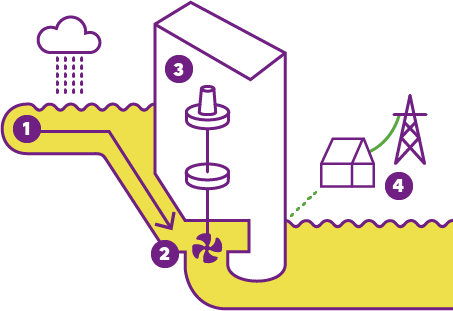

Our hydropower plants use the drop heights and flows of our rivers. This is called potential energy and this is produced when water moves from a higher (1) level to a lower one. We build dams (1) adjacent to hydroelectric plants in order to achieve greater level difference and better control.

To make use of the potential energy, water passes through a turbine (2) in the hydropower plant. The water flows past the blades of the turbine, which then rotates and creates kinetic energy, which is then converted into electrical current in a generator (3).

The current then continues on from the generator to a transformer (4) which raises the voltage and sends the current into the power transmission and distribution network.

1.The water is at its highest level when it is in the hydropower plant’s dam.

2. The water passes through the power plant’s turbine.

3. The generator converts the turbine’s rotation into electrical current.

4. The transformer increases the current’s voltage so it can be sent on the long route through the power transmission and distribution network.

Energy from a planet’s natural cycle

Hydropower is a part of the planet’s natural cycle and is fully renewable. Therefore, it is an important energy source for the future. However, there are challenges in maintaining a good environment in the areas where the power plants and dams are built – challenges that we are working hard to tackle in the best possible way.

Hydropower releases almost no emissions into the environment. However, biological diversity is affected when the water flows are altered, which affects fish migration and the flora on the shoreline.

When a hydropower plant is built, strict requirements are imposed on the power company that is in charge. We adhere to these requirements and work tirelessly to maintain a healthy environment in the watercourse.

This is how we work to maintain the natural environment

Together with the rest of the industry, we are conducting research projects that study environmental effects and examine methods that can minimise the impact of hydropower. We are taking some of the following measures:

- drawing water from the old river channel while at the same time building submerged dams, which helps to ensure that some of the natural flora and fauna remain

- building migration routes which enable the fish to swim past the facilities

- building artificial spawning areas which make it easier for fish to reproduce.

We are developing our hydropower

The hydropower plant in Storforsen is our newest facility, a modern example which demonstrates that hydropower can be used in a way which is gentle on the environment. We have designed the facility with respect to the scenic environment which surrounds it.

The facility has a spillway dam that is 43 metres long, and this ensures a natural variation in the river’s water level upstream from the dam. The side-drawing method is adapted so as not to interrupt the flow of the 500-metre-long stretch of river, which is good for the aquatic organisms. We have also created spawning areas for the fish.

We have built a beautiful wooden bridge over the dam which blends into the natural scenery and gives visitors and residents of the area greater access. We have preserved parts of the dam from the timber floating era.

You can read more below about our environment-related measures at Storforsen:

- Oil-free impeller hubs and oil-free transformers.

- High pressure function for oils in hydraulic regulation systems.

- PVC-free cables.

- Recovery of waste heat from stators and bearings.

- No oil or electricity consumption in the dam due to the dam being designed as a spillway dam.

- Subtle encroachment in the area with buildings and facility elements.

- Measures while building that minimise the impact on the environment.

In 2014 we cooperated with other power companies and Luleå University of Technology in a project to develop a new type of environmentally acceptable, small-scale hydropower plant.

The purpose was to develop small-scale hydroelectric power which is both financially and environmentally sustainable. We installed a new type of turbine which facilitates the downstream migration of fish and which does not require oils to be operated. When oils are required there is a risk of leakage and pollution of the water around the power plant.

In 2014, we started a two-year project at Hednäs power station. The aim of the project is to facilitate fish migrating past the station as the existing fish ladder has not functioned properly since the beginning of the 2000s, despite continuous adjustment. In this project, we collaborate with the fish conservation areas in Åby River, the river protection association Älvräddarna, the non-profit organisation for Baltic rivers Östersjölaxälvar i samverkan, the effected municipalities and the County Administration Board.

From rivers in Norrland to the rest of Sweden

Our hydropower comes from the mighty rivers in the north. At present we operate 14 larger facilities, and most of them are close to our headquarters in Skellefteå. Proximity is key; it gives us easy access to the power plants and good control over our energy sources.

Sällsjö

Year of construction: 1962

Electrical output: 160 MW

Average annual production: 350 GWh

Krångfors

Year of construction: 1926

Electrical output: 62 MW

Average annual production: 350 GWh

Selsfors

Year of construction: 1944

Electrical output: 61 MW

Average annual production: 265 GWh

Finnfors

Year of construction- old station: 1906

Year of construction – new station: 1955

Electrical output: 54 MW

Average annual production: 237 GWh

Granfors

Year of construction: 1952

Electrical output: 40 MW

Average annual production: 207 GWh

Rengård

Year of construction: 1970

Electrical output: 36 MW

Average annual production: 203 GWh

Båtfors

Year of construction: 1962

Electrical output:42 MW

Average annual production: 201 GWh

Grytfors

Year of construction: 1968

Electrical output: 31 MW

Average annual production: 189 GWh

Rebnis

Year of construction: 1974

Electrical output: 64 MW

Average annual production: 142 GWh

Sikfors

Year of construction: 1990

Electrical output: 33 MW

Average annual production: 139 GWh

Bergnäs

Year of construction: 1989

Electrical output: 8 MW

Average annual production: 30 GWh

Slagnäs

Year of construction: 1989

Electrical output: 7 MW

Average annual production: 32 GWh

Sädva

Year of construction: 1985

Electrical output: 31 MW

Average annual production: 119 GWh

Klippen

Year of construction: 1994

Electrical output: 27 MW

Average annual production: 100 GWh

Storforsen

Year of construction: 2007

Electrical output: 4,7 MW

Average annual production: 20 GWh

Safety first

With over 100 years of experience of hydropower, we have developed technologies and routines that prioritise safety. We have our own organisation that works with satisfying the increasingly stringent safety requirements imposed on dams.

Dam security – working preventatively and being prepared

Dam security mainly centres around preventing problems, but it also means being ready if an accident occurs. An example of a preventative measure is that we always calculate based on the worst possible flows – which are estimated to occur every 10,000 years – when we build or reinforce our dams.

In order to ensure that the hydropower dams are safe, we have our own organisation that deals with these issues. We collaborate closely with Skellefte River’s water regulation company, which runs the project Samordnad beredskap (Coordinated preparedness). The aim of the project is to manage the situation along the entire river and minimise damages if a dam were to break.

Operational safety – careful planning

To ensure that operational safety is as high as possible, we carefully plan our maintenance. Our objective is to ensure that the facilities function and are secure during the 40-year periods that pass between larger renovations of equipment and machinery.

Safe electricity – for both you and the environment

Our hydropower plants are managed from an operating centre, which is responsible for monitoring water legislation and other applicable regulations. The water must flow safely through the system of dams and power plants. The staff at the operating centre ensure that the electricity is supplied to you when you need it and that this takes place in a way which is safe both for you and for the environment.

Oil spills – preparing for the unexpected

We continuously develop and maintain our facilities to ensure that there are no oil spills. If, despite this, an oil spill should occur, we have a unique collaboration with the emergency services. Specially trained staff and environmental ambulances are ready to quickly minimise any damage.